To Fault Find or Not?

Not all oven faults are sensible to repair

WHAT WE DON'T DO

We Don't Do Cooking Events. We can deal with objective observable deviations from the standard operating function! What we can't or more accurately don't get involved with is subjective expectations. The most common is related to a recipe! The discussion always starts with: "The recipe states the oven must be 180 degree and the cook time is say 20 minutes". There is no way for us to verify this! We don't cook or prepare product for cooking. In other words; it's just not sensible to undertake a cooking event to verify the issue.

Subjective matters include things like smell, taste, too long, too hot, etc. We need accurate, reliable facts. Most customer can only provide details like: it's taking too long to cook. While this description helps, it only points us in a very rough direction. Meaning more time to diagnose the problem. Instead of saying "it took too long", we need "it took 10 minutes to raise 20 degrees". Sure, in your head you're saying to yourself; "I'm not a technician how would I know!" Every body that cooks typically uses some sort of timer. And for most people they have a thermometer to verify the product is cooked. If not, spend $40-50 and get a thermometer. In the long run, we can do the temp/time validation for you but, that means time to heat and test the oven and it means we can't work on the oven once it's hot. We waste time waiting for it to cool down. A good percentage of time, customers learn that the oven is actually cooking normally and the recipe is not turning out as expected.

We don't do "manufacturing expectations"! What does that mean? It means manufacturers have said fan forced cooks evenly across the oven; this is just not true. Fan Forced improves evenness, but it can't over come the problems associated with solid trays blocking the path of air flow, it can't make a circular fan move air evenly in a square shaped oven.

Oven door design is intended to stop most users from burning themselves by accidentally touching the door. But that doesn't mean it's not hot or isn't going to cause sensitive skin to be left with a mark. But, if you want the correct answer; get your user manual out and find the section that stipulates the temperature the outer door is allow to operate at.

The same goes for fan noise. How much noise should a fan make. And when is that noise more than is reasonable. Again, check your user manual for the decibel allowance. I'm being a smart arse. If you find this sort of information, I'd love to hear about it.

The same goes for how long you're allowed to use your oven or how often the manufacture intends for you to use your oven. Is it 2 times a week for an hour a time at 200 degrees or 18 times a week for 3 hours a time at various temperatures? Again, no such answer.

We don't do cleaning events. While we are at your home repairing your oven we don't get involved in cleaning events. If you want your oven cleaned, then please use an oven cleaning service. This means if we pull the oven out it's not a chance for you to clean! If we have to pull your oven door apart to replace the hinges etc. it is not an opportunity to clean!

While your kitchen is you domain and as such you have the absolute right to enter and do what you like in there. At the same time it is our workplace. And as such we have obligations to make sure that the workplace is safe for both you and ourselves. The stainless steel panels are sharp and we have seen many customers slice their fingers cleaning panels we remove. Glass doors have imploded because customers don't know they are safety glass and can implode if twisted when cleaning. Often customers like to point to things (mainly what looks like items that need cleaning) they don't normally get to see, only to be shocked when I grab the offending appendage to stop them from touching electrified components.

You don't go into your mechanics workshop to clean your car just because they remove the seat to undertake a repair. It's why we ask customers to stay clear of the works being undertaken.

We don't do smells. Sure smell is one of the senses we use to determine where hot joints might be. The main reason this is a difficult issue is because it is so subjective. There are really very few people that have the same smell perception. Ovens emit smells and they change over time and heat. Having lived in a house with 3 women I can attest to the fact that they have far keener sense of smell than me. What I can't smell can give them a headache. That doesn't mean the smell has to be banished forever. I can't stand incense, but other see it as soothing. Just because I can't stand it doesn't mean it should be banned. The same can be said for oven. Sure some smells are indicators of a change and sometimes that can lead to parts that are in the process of failing. This is not intended to mean we don't attend an oven that smells like some electrical burning smell. It's just means sometime we might not be able to eliminate the smell every time.

Fault Finding

Diagnosing oven problems

DIAGNOSTICS

To fault find or not?

Fault finding is an inductive process if the fault is not apparent during observation. Fault finding is not always a linear process. If it costs $400 to clearly identify every fault or soon to be realised fault and it costs $600 to replace the oven; then no one will repair anything. We repair many ovens every day and most are completed for less than $260.00. So, for most customers it makes good sense to change the obvious fault rather than pay for diagnostics. Having said that, only the customer knows if their oven has been subjected to a variety of issues over time. As a technician we can only judge from what you describe. If you go to a mechanic and ask for your tyre to be replaced and then find the motor dies a few weeks later, when you knew full well that the engine had been having issues from some time; then the mechanic can’t be blamed for changing the tyre. However, if you start the conversation with context that includes the motor issues then the mechanic will provide repair options for you to consider.

Having said the above; some faults are not so readily diagnosed and can take time to determine what the cost might run into. We have to take a sensible approach and aim for an economical outcome. So, if you want absolute diagnosis, please make that clear at the outset and expect to pay for it; separate from any fixed price offer.

Good inductive reasoning is very reliant on you the customer. If you tell us the oven is not heating, we know the probable outcome will be a new element. Many if not most elements display visual cues that takes seconds to verify that it's faulty. Much like your car tyre. No diagnosis necessary for a flat tyre. On the other hand, if you tell us the oven is getting too hot, we're not going to be checking your elements! So, if you know the element is cracked and falling apart but still working tell us, because otherwise will be likely conclude the thermostat is the culprit and leave the element to its fate.

The worst outcome is your observations simply aren't correct or are vague. This means we must spend more time going through a possibly unnecessary tests. Time wasted equals money wasted! The more you can be sure about what you’ve observed and clearly communicate them, the quicker/cheaper we can resolve your issues.

Electronic Diagnostics

Need a new Electronic Control Board; read on!

ELECTRONIC PARTS

Risks associated with fitting electronic parts

So, we’ve had quick look at your oven/stove and advised it is likely a “Control Board” fault. “Likely” being the operative word! Because, no one in our industry does diagnostics on a faulty control board. To do this takes schematics and component specifications and expensive test equipment that is better suited to a lab than a van.

Further, the suppliers of the electronic parts will not refund any electronic parts once removed from its packaging. And for good reason, PCB’s are electrically sensitive, and can be damaged by inline electrical parts, or static electricity etc. Suppliers have no way of knowing what happens to the PCB once removed from its package, so they can’t or won’t take these items back.

Deductive reasoning

Not to get to technical; but for most oven/stove faults, we use deductive reasoning. Which basically means we can test certain conditions of a device which will give us a high probability that the device is faulty or not. For instance, a fan motor with an open circuit will not work unless the circuit is closed. It’s straight forward, we measure the resistance and we look for a specific result.

Simple example (Wikipedia)

An example of a deductive argument:

- All men are mortal.

- Socrates is a man.

- Therefore, Socrates is mortal.

The first premise states that all objects classified as “men” have the attribute “mortal”. The second premise states that “Socrates” is classified as a “man” – a member of the set “men”. The conclusion then states that “Socrates” must be “mortal” because he inherits this attribute from his classification as a “man”.

Inductive Reasoning

Inductive Reasoning is basically the opposite of Deductive Reasoning. Inductive reasoning starts with a conclusion and deductive reasoning starts with a premise. Inductive reasoning moves from specific instances into a generalized conclusion, while deductive reasoning moves from generalized principles that are known to be true to a true and specific conclusion.

We use this logic to deal with an unrepresented fault. In other words where we can’t specifically test the PCB for a fault, we test the rest. If the rest is okay; then the PCB is the most likely the culprit. Most likely being the operative word!

But to prove a printed circuit board (PCB) is faulty means we must spend the time verifying the other electrical devices like the are correct. To do this we rely on resistance readings, micro-ohm reading, thermal scans, temperature readings etc. This can mean having to isolate each device and verify the correct resistance readings or other readings. Sadly, resistance is only one element of ohms law. Which means it doesn’t provide absolute positive proof that the device is functioning correctly. Same with a thermal reading, a low differential reading might imply no cause for alarm. However, using a different cooking function might change the current being drawn is just enough for what is known electrically as the pinch effect to kick in, which can then dramatically vary the differential reading without changing the temperature range. Variables are the crucial factor in determining an unrepresented fault – inductive fault finding.

Economics

Unfortunately, the cost of the diagnosis time can be as expensive as (and sometimes more expensive) than the repair itself and generally prohibits an economical outcome.

Example: (not real values) | ||

|---|---|---|

Call out

| $100 | |

Diagnosis Labour | 1 1/2 hour | $165 |

Electronic Board | $220 | |

Installation Labour | 1/2 hour | $55 |

Total | $540 |

Given the cost of the machine when new was say $650.oo, it is difficult to justify proceeding with the above repair.

There are many factors that would drive any final decision, such as age, condition, brand (original value), new price etc. For instance, if the machine was just 2 years old and a power outage had caused the PCB to be damaged then it might be sensible to repair the machine. But if the machine was 7 years old and was not in good nick then repairing the machine would not make much sense.

So, the reason this page exists is to save our technician from having to spend 15 minutes trying to explain these details so that you can make an informed decision. And to advise you (the customer) that if you do decide to go ahead and replace any electronic part such as the PCB, we won’t be held liable for the outcome. And once we remove the electronic part from its packaging, you the customer are liable to pay for it regardless of the outcome. Further the electronic part cannot be returned.

To diagnose or not?

We attend your home and quickly advise the hinges need replacing and one of the elements is down to earth. We tally it up and quote $300 (not a real price). We change to parts and start the testing process, while we do the paper work. This would be the average outcome of 80% of our work. But the other 20% when we get the oven going, we find the thermostat is unable to control the temperature. In hind sight everyone would agree the thermostat should have been checked before replacing the element. And, we won’t argue! In hindsight that’s correct. Setting that aside, you decide to proceed as it’s still economical to replace the thermostat. Great, oven is running while we complete the paper work. Ohhh Nooo, the fan starts to make a horrible noise after it has been hot for a while. In hindsight it would have been smart to test the fan before doing the element, hinges and thermostat. Again, we can’t disagree! The only caveat being the term “Hindsight”. It’s an expensive oven and changing the fan motor is still the most economical choice. We do the paper work all over again, the oven is now ticking away beautifully. We take payment and get on our way to our now late next job! On the way to our next job, you call and tell us the unit has tripped the safety switch as you have been running the oven since we left to give it a good test. We make a time and return, only to find the oven working fine. Grumpy, both of us, we agree it seems to be working fine and you pay for a wasted call. Sure, enough to add injury to insult you call about an hour later and advise the oven has tripped the breaker again. We make a time and come out again. This time though we start the diagnostic process.

What a horror story! Each step in the above process is a progression toward this almost absurd and rare as rocking horse pooh event. And for sure, somewhere along that progression it would have been smarter to start with diagnosis. However, there are factors that have bought us all to this horror point, the customer knew that the fan was noisy when it gets hot, but they didn’t think to mention that while we were dealing with the more obvious first issues. The customer also new that the oven tripped on the odd occasion, but never thought this was relevant to our approach; “diagnose or not”. Equally, we don’t experience this horror event very often. Hence, we let our guard down and do the mundane, routine repairs most days, weeks, months sometimes years before another horror event comes around to shock us back into reality. Things can go wrong and it’s no ones fault. Why, you ask didn’t you start with diagnosis! Well, another very good reason is “hot”! Yes, ouch that’s hot! Many difficult to find faults only present under hot conditions for some considerable time. Sometime hours before they present. And no one wants to pay for tests that don’t contribute to a determination. While we carry Adelaide leading test capability, such as Thermal imaging, Micro Ohm contact testing, live mA recording, ramp RCD testing, tachometer readings etc. These are not cheap processes and may not each be necessary. At the beginning of the above horror show, we might have started with a temperature test to prove the thermostat works correctly, which means the oven would have been “hot” eliminating our ability to replace the thermostat until the oven cooled. This process would have probably identified the noisy fan as well. But would not have uncovered the earth fault. That requires alternate test methods. In the first part of the process, we have to determine if the oven is at fault or if the circuit is compromised. Often a safety switch protects a variety of circuit. If you have a fridge, toaster, dishwasher and kettle all on the same circuit, each of this might contribute to a cumulative effect causing a trip. Add to this the fact that almost no RCD trips at 30mA as designated. Most trip around 25mA. Then if we divide equally the leakage for each contributing circuit it may only be allowing 5mA of leakage for the oven. Today it is regulation that every oven must be under its own RCD allowing a full 30mA. If this were the scenario then possibly the leakage of the oven might never be an issue. Once we have determined it is not a compromised circuit, we then need to conduct an insulation test. This would identify say 80% of earth faults. But, in our horror story, not the case. To find this fault we need to conduct a live mA leakage test on each component of the oven. Again, the operative word being “hot”! We already know now that the hot condition is a prerequisite of this fault presenting itself. To check each device while the oven is in its hot state is no minor feat. In point of fact, by this stage in the proceedings we have probably well past the repair cost of the overall job. Hence the reticence for proceeding down the diagnostic process first.

This isn’t intended as a means for you the customer or even us to determine which step and when to apply it. The factors that influence these choices are many and varied. If you have a Bunnings $500 oven then most of that is out of the ball park at element and hinges.

Bottom line, we do our best and hope the horror story remains rare! Bearing in mind our best compared to most is competitors is significant in its own right. Many wouldn’t know how to apply half the test mentioned here, much less have the threshold data for determining what the results mean.

WE JUST FIX OVENS

We use solve recipe as a reference point!

Ovens at their core are just boxes with elements, fans and a thermostat to control the heating temperature. We are mere electricians and don't claim to be chefs or cooks or other recipe worshipper. If the oven seals, the fan runs, the correct temperature is achieve, then we are rendered moot. What we don't do is deduce why a certain recipe does or doesn't result as the creator intended.

The reasons for what might be causing a certain cake to not come out exactly as intended, and can be many and varied. We can remove most of the oven contribution to the problem quite efficiently. What we can't do is prove to the "baker" that it's not the oven. There really aren't that many factor we can change that will solve all cooking frustrations.

When the customer says that the cake is taking longer than normal to cook, or isn't cooking evenly etc. there are really only two outcomes. 1. The oven is faulty and we can reasonably fix that within a short period of time. Or 2. It's not the oven. Mmmm I hear; and then the enigmatic "but why" escapes the cooks lips and we want to run for the hills! The variables on the cooking side of the process are many times more than the oven's operational considerations. If we consider the most basic criteria for an oven cooking correctly, temperature is the most significant. So long as we can establish a consistent cooking temperature, that's almost 80% of the issue dealt with. On the cooking side we have many more unknowns. What was the temperature of the product before being put in the oven. What was the moisture content of the product? Because a cooking event is really only one process; removing moisture!

When we think about baking a cake who's to say the recipe ever produced a consistent result as seen in the pretty marketing image. What size egg was used? What type of flour was used i.e. protein content? Was the oven at temperature when the product was placed in the oven or bought up to temperature? Was a fan forced setting used, or perhaps a fan assist setting. Was it gas that was used when producing the recipe? Was it a 900mm oven or a 600mm oven. The variables are so many and the time it would take to resolve each variable is significant compared to the cost of replacing the thermostat.

What we hope this dialogue will do is give our customers a reason behind the many questions we probably asked when you said the cake isn't cooking like it used to. And, when we charge you for confirming the oven is working correctly; it must be related to the recipe and expectation that we can't help with, we don't want to end up being blamed by the cook for not fixing the problem.

Book now and save!

Did you know there's a 10% discount for booking online?

***No Tax Invoice***

This form - and the 10% discount - is for domestic customers only.

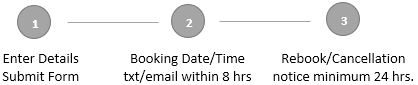

You have made a booking; a confirmation will be provided within 8 hours!

If you are a Rental Property Owner/Manager/Tenant/Commercial Operator please use the Rental booking form.

If you use this Booking Form you will not receive a “Tax invoice”.

Electric Oven Repair

Book online and save 10%

Booking online saves time, errors and provides a written record of the appointment details. We pass this saving on via a 10% discount. Please make sure your email/mobile phone number is correct, as we sms/email a time and date confirmation. If the date you have selected is not available we will continue to communicate via email to finalise a time and date confirmation. By submitting a booking means you have agreed to have us attend your property to repair your appliance and have accepted our terms and conditions. We will send you a date and time confirmation by sms/email as you choose. Your receiving the date and time confirmation does not negate your booking obligations.

Please note* This form is for privately owned residences only. If you are a Property Owner/Manager or Tenant; please use our rental property form.

Note*

We carry a selection of spares for the most common faults and should our technician not have the required parts on board, there is no additional Service Call Out Charge for the return visit. Warranty claims must be submitted in writing, and when applicable are conditional upon all accounts and payments being in order and fully settled as per our trading terms. Things go wrong! If you haven’t received your booking confirmation by the time you anticipated; call! The amount of incorrect phone numbers/ email addresses etc. we receive means you might not receive your confirmation as anticipated. Ring us before you go off making alternate arrangements. All postponements or cancellations must be submitted in writing 24 hours prior to the appointment time. Failure to do so in a timely manner will incur cancellation charges.

Contingency Bookings

If you are not sure what Contingency bookings are; then read on! It’s when a customer makes a booking, but then rings around to find another repairer who can maybe make it earlier! This is not just frowned upon, but makes up a big part of lost revenue for any repair operation. So please; do the ring around before making a booking. And then if we end up your best option, please then make a booking.

*During business hours. Over-night submissions will be responded to the following business day.

Adelaide's first and only dedicated oven repair service

The licensing, skills, equipment and results are very different. Choose wisely!

Our Service Area

Workshop Location - Parcel Point

Keeping you safe at home

Social distancing

Avoid contact

Contactless Payment

CONTACT

COMPANY INFO

ABN: 13 145 484 313

Office Ph: 0411 377 955

Office Hrs: Mon - Fri, 9:00am - 5:00pm

© 2010 ~ 2024 Adelaide Corporate Pty Ltd

Adelaide 5000 | Aberfoyle 5159 | Adelaide Airport 5950 | Albert 5014 | Alberton 5014 | Allenby 5009 | Angle 5010 | Ascot 5043 | Ashford 5035 | Athelstone 5076 | Athol 5012 | Auldana 5072 | Beaumont 5066 | Bedford 5042 | Belair 5052 | Bellevue Heights 5050 | Beulah 5067 | Beverley 5009 | Black Forest 5035 | Blackwood 5051 | Blair Athol 5084 | Bowden 5007 | Brahma Lodge 5109 | Brighton 5048 | Broadview 5083 | Brompton 5007 | Brooklyn 5032 | Brown Hill Creek 5062 | Burnside 5066 | Camden 5038 | Campbelltown 5074 | Cavan 5094 | Chandlers Hill 5159 | Cheltenham 5014 | Clapham 5062 | Clarence Gardens 5039 | Clarence 5034 | Clearview 5085 | Clovelly 5042 | College 5069 | Collinswood 5081 | Colonel Light 5041 | Coromandel East 5157 | Coromandel Valley 5051 | Cowandilla 5033 | Crafers 5152 | Crafers West 5152 | Craigburn Farm 5051 | Croydon 5008 | Croydon P 5008 | Cumberland 5041 | Darlington 5047 | Daw 5041 | Dernancourt 5075 | Devon 5008 | Dover 5048 | Dry Creek 5094 | Dudley 5008 | Dulwich 5065 | Eastwood 5063 | Eden Hills 5050 | Edwardstown 5039 | Enfield 5085 | Erindale 5066 | Ethelton 5015 | Evandale 5069 | Everard 5035 | Exeter 5019 | Fairview 5126 | Felixstow 5070 | Ferryden 5010 | Findon 5023 | Firle 5070 | Fitzroy 5082 | Flagstaff Hill 5159 | Flinders 5025 | Forestville 5035 | Frewville 5063 | Fulham 5024 | Fulham 5024 | Fullarton 5063 | Gepps Cross 5094 | Gilberton 5081 | Gilles Plains 5086 | Gillman 5013 | Glandore 5037 | Glanville 5015 | Glen Osmond 5064 | Glenalta 5052 | Glenelg 5045 | Glengowrie 5044 | Glenside 5065 | Glenunga 5064 | Glynde 5070 | Golden Grove 5125 | Goodwood 5034 | Grange 5022 | Green Fields 5107 | Greenacres 5086 | Greenhill 5140 | Gulfview Heights 5096 | Hackney 5069 | Hallett Cove 5158 | Hampstead 5086 | Happy Valley 5159 | Hawthorn 5062 | Hawthorndene 5051 | Hazelwood 5066 | Heathpool 5068 | Hectorville 5073 | Hendon 5014 | Henley Beach 5022 | Henley Beach South 5022 | Highbury 5089 | Highgate 5063 | Hillcrest 5086 | Hilton 5033 | Hindmarsh 5007 | Holden Hill 5088 | Hope Valley 5090 | Hove 5048 | Hyde 5061 | Ingle Farm 5098 | Joslin 5070 | Kensington 5068 | Kensington 5068 | Kensington 5068 | Kent Town 5067 | Keswick 5035 | 5035 | Kidman 5025 | Kilburn 5084 | Kilkenny 5009 | Kings 5034 | Kingston 5049 | Kingswood 5062 | Klemzig 5087 | Kurralta 5037 | Largs Bay 5016 | Leabrook 5068 | Linden 5065 | Lockleys 5032 | Lonsdale 5160 | Lower Mitcham 5062 | Lynton 5062 | Magill 5072 | Malvern 5061 | Manningham 5086 | Mansfield 5012 | Marden 5070 | Marino 5049 | Marion 5043 | Marleston 5033 | Marryatville 5068 | Mawson Lakes 5095 | Maylands 5069 | Medindie 5081 | Medindie 5081 | Melrose 5039 | Mile End 5031 | Mile End South 5031 | Millswood 5034 | Mitcham 5062 | Mitchell 5043 | Modbury 5092 | Modbury Heights 5092 | Modbury 5092 | Morphettville 5043 | Mount Osmond 5064 | Myrtle Bank 5064 | Nailsworth 5083 | Netherby 5062 | Netley 5037 | Newton 5074 | North Adelaide 5006 | Brighton 5048 | Plympton 5037 | Northfield 5085 | Northgate 5085 | Norwood 5067 | Novar 5040 | Oakden 5086 | Oaklands 5046 | O'Halloran Hill 5158 | Old Reynella 5161 | Ovingham 5082 | Panorama 5041 | Para Hills 5096 | Para Hills West 5096 | Para Vista 5093 | Paradise 5075 | Parafield 5106 | Parafield 5107 | Holme 5043 | Parkside 5063 | Pasadena 5042 | Payneham 5070 | Payneham South 5070 | Pennington 5013 | Plympton 5038 | Plympton 5038 | Pooraka 5095 | Port Adelaide 5015 | Prospect 5082 | Queenstown 5014 | Redwood 5097 | Regency 5010 | Renown 5008 | Reynella 5161 | Reynella East 5161 | Richmond 5033 | Ridgehaven 5097 | Ridleyton 5008 | Rose P5067 | Rosewater 5013 | Rosslyn 5072 | Rostrevor 5073 | Royston 5070 | Salisbury 5108 | Salisbury Downs 5108 | Salisbury East 5109 | Salisbury 5109 | Salisbury Plain 5109 | Salisbury South 5106 | Seacliff 5049 | Seacliff 5049 | Seacombe 5047 | Seacombe Heights 5047 | Seaton 5023 | Seaview Downs 5049 | Sefton 5083 | Semaphore 5019 | Semaphore 5019 | Semaphore South 5019 | Sheidow 5158 | Skye 5072 | Somerton 5044 | South Brighton 5048 | South Plympton 5038 | Springfield 5062 | St Agnes 5097 | St Georges 5064 | St Marys 5042 | St Morris 5068 | St Peters 5069 | Stepney 5069 | Stirling 5152 | Stonyfell 5066 | Sturt 5047 | Tea Tree Gully 5091 | Tennyson 5022 | Thebarton 5031 | Thorngate 5082 | Toorak 5065 | Torrens 5062 | Torrensville 5031 | Tranmere 5073 | Trinity 5068 | Trott 5158 | Tusmore 5065 | Underdale 5032 | Unley 5061 | Urrbrae 5064 | Vale 5081 | Valley View 5093 | Walkerville 5081 | Walkley Heights 5098 | Warradale 5046 | Waterfall Gully 5066 | Waterloo Corner 5110 | Wattle 5066 | Wayville 5034 | Welland 5007 | West Beach 5024 | West Croydon 5008 | West Hindmarsh 5007 | West Lakes 5021 | West Lakes Shore 5020 | West Richmond 5033 | Westbourne 5041 | Windsor 5087 | Wingfield 5013 | Woodville 5011 | Woodville 5012 | Wynn Vale 5127 | Yatala Vale 5126

© copyright all right reserved